Corrosion Monitoring Techniques

3. CORROSION MONITORING TECHNIQUES

There exist a number of techniques which may be used to monitor the effects of occurrence of corrosion. These techniques basically fall into seven categories

1. CEION

2. Electrical Resistance Monitoring

2. Electrochemical Methods

3. Hydrogen Monitoring

4. Weight Loss Coupons

5. Non-Destructive Testing (NDT) Techniques

6. Analytical Techniques

3.1 CEION

CEION is a new ratiometric metal loss measurement device with resolution that is at least 100 times better than existing ER based devices. It is ideal for monitoring oil/gas production and processing systems. A technology that is just as capable of driving the real-time control loop of an inhibitor pump as it is of operating without maintenance between planned shut downs. CEION™ is also first choice technology for sub-sea, sub-surface applications where access and reliability are key factors but fast response is still essential. CEION is also ideally suited to measuring sand erosion in producing systems and a specific set of sensor designs has been developed for this application.

3.2 ELECTRICAL RESISTANCE (ER) MONITORING

The ER method of corrosion monitoring is one of the most widely used techniques and consists of determining the change in resistance of a metal element as it corrodes in a process environment. The action of corrosion on the element serves to decrease the cross sectional area thereby increasing the electrical resistance. The element is usually in the form of a wire, strip or tube, and if the corrosion is roughly uniform, a change in resistance is proportional to an increment of corrosion. Estimates of the total corrosion over a period may me obtained from successive readings. A simple formula converts to an average corrosion rate.

Electrical resistance probes are rugged and well adapted to any corrosive environment. The ER technique is well proven in practice and is simple to use and interpret. ER monitoring permits periodic or continuous monitoring to be established for one or a multiple number of probes. Corrosion can thus be related to process variables, and the method is one of the primary on-line monitoring tools. The major advantage is its ability to measure corrosion in any environment, liquid, gas or particle streams.

3.3 ELECTROCHEMICAL METHODS

Since corrosion is an electrochemical process, it is not surprising that there exist a number of electrochemical methods for corrosion monitoring. The two electrochemical techniques which are most widely used are Linear Polarisation Resistance Monitoring and Galvanic Monitoring, also known as Zero Resistance Ammetry.

The essential difference between ER and Electrochemical techniques is that ER measurements provide information on total loss of material, whereas electrochemical techniques give rate information.

3.3.1 LINEAR POLARISATION RESISTANCE (LPR) MONITORING

The LPR technique attempts to respond on a microscopic scale the microscopic corrosion cells existing within the plant. LPR measures the corrosion current flowing between anodic and cathodic half cells. Measurements are made by applying a small voltage (≈ 10 – 30mV) to a corroding metal electrode and measuring the resulting current flow. The ratio of voltage to current – the polarisation resistance – is inversely proportional to corrosion rate.

LPR monitoring provides an instantaneous measure of corrosion rate and may, for example be used as a method for optimising corrosion inhibitor injection. The LPR technique is restricted to aqueous solutions and best results are obtained in highly conductive media. To permit more accurate measurements in solution of higher resistivity, systems have been designed which utilise 3 electrode probes.

3.3.2 GALVANIC MONITORING (ZERO RESISTANCE AMMETRY)

The principle of the Galvanic technique relies on the fact that when two different metals are immersed in an aqueous liquid they assume different electrode potentials. If these metals are connected externally, a current will flow between them. This current is the result of the half cell reactions taking place simultaneously causing the dissolution (corrosion) of the more negative metal in the solution and the reduction of any available species such as oxygen at the surface of the more positive electrode.

If oxygen is excluded from the system, the reduction process is suppressed and the galvanic current falls to a very low level reflecting the reduced rate of corrosion.

Galvanic measurements are particularly applicable to the detection of the ingress of oxygen into systems protected by de-aeration. Also, they provide a rapid, continuous method for assessing corrosive conditions in aqueous flows.

3.4 HYDROGEN MONITORING

Hydrogen Monitoring is an important facet of corrosion monitoring, since the detection of hydrogen provides an indication that corrosion is taking, or has taken place.

In particular, in situations where plant is exposed to wet sour gas (H2S), or acid conditions, the generation of hydrogen is of primary concern.

Under such conditions hydrogen may be directly absorbed into the fabric of the plant and produce blistering, embitterment, stress corrosion cracking and other hydrogen induced problems.

Hydrogen monitoring probes exist which can be either inserted into the plant in order to measure the presence of hydrogen, or conversely attached to the exterior of the plant in a saddle mode capable of detecting the diffusion of hydrogen through the plant.

3.5 WEIGHT LOSS COUPONS

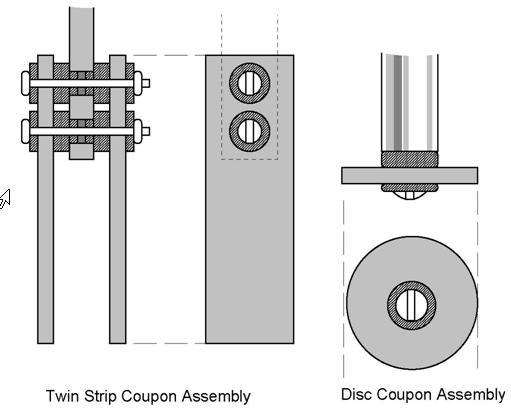

Weight loss coupon monitoring is the oldest method for assessing the corrosivity of an environment on a specific material and involves exposing a specimen (coupon) of the material to the environment for a given duration, and measuring the resultant weight loss. The coupons can be in the form of discs, rods, plates or of any convenient shape.

Coupons are not an instrumental method, and require extensive manual involvement in order to provide information. Also, coupons only provide integrated corrosion loss data. However, the advantages of coupons include:

Visual interpretation

Deposits can be observed and analysed

Weight loss can be readily determined

The degree of localisation of corrosion can be observed and

measured.

FIGURE 3.1 Examples of Weight Loss Coupons

3.6 NON-DESTRUCTIVE TESTING (NDT) TECHNIQUES

A comprehensive range of NDT techniques exist which complement the ‘instrumentation’ techniques previously described. These include ultrasonics, radiography, thermography, eddy current measurement and various others. Such techniques usually fall into the area of plant inspection.

3.7 ANALYTICAL TECHNIQUES

A number of analytical techniques are used to look at the process fluid chemistry. This usually involves drawing off fluid samples for laboratory analysis. Areas of interest under this heading are iron counts, chloride counts, oxygen, conductivity and pH measurements, flow measurements and temperature.

3.8 SUMMARY

In practical corrosion monitoring programmes it is usual for several corrosion monitoring techniques to be used, with some element of correlation being established.

The preferred methods are Coupon and CEION or ER monitoring, with emphasis on the latter, since CEION & ER monitoring provides useful information on a day by day basis and measurements may be made without the requirement for the probe to be retrieved from the system.